Precision Machining and Manufacturing

The precision machining is the manufacturing process in which the machining of parts is carried out to produce parts and components by removing excess material from raw bar to produce the work piece. In precision manufacturing the machining is done to close tolerances to desired dimensions of finished product. In this machining process the large pieces to finished product to more precise parts so that they can reach to exact dimension. In this machining more accuracy to close dimensions is maintained by using narrow tolerances. The word precision machining relates to the machining operation with very low tolerances in dimension, very close geometric tolerances, complex shape and very high surface finishing operations. The machining operation produces high rate of production and close dimension with less wastage of material and less material removal with better efficiency. The precision machining is used in various application such as very tiny parts, watch parts, high dimensional accuracy, polished surface components of complex shape and sizes.

What is precision Machining?

The precision machining is the machining operation done by manufacturer to convert raw material to the exact dimensions into product. The raw piece of material is saved to the desired shape and very close size by precision manufacturer cncfirst. The precision manufacturing is done by using computer aided design and computer aided manufacturing. It uses the most precise and accurate measuring system and the material is cut to exact specifications or with closer dimensional accuracy. It is the process which removes minimum excess material from work piece and providing close tolerances with very good surface finish. It is performing shaping of material of large pieces into more precise parts which is near to exact specifications.

The precision machining is used for parts which require

- Very Precise dimensions

- Require Lower material cost

- Require Higher life

- Less rejection of parts

- Higher level of safety

- Interchangeable products

- Better quality control

- Less wear and fatigue

- Better quality and surface finish

- More miniature parts

1. Working Procedure of Precision Machining

The precision machining operations are done by computer-controlled machine known as CNC machine. The computer aided drafting process is used to prepare drawing of part of computer in the drafting packages like AutoCAD or solid works or fusion. These CAD drawings are used to produce part programs or NC programs which contain G and M codes for machining raw piece to given dimensions. These are known as CAM files which are imported to the machines and they perform the operations with great precision and complex design of parts and components.

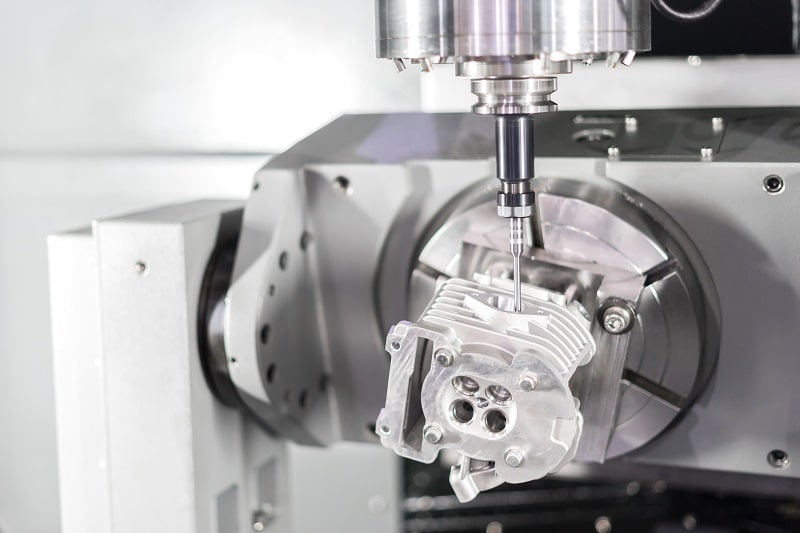

2. Precision Machining Tools

The precision machining tools used are lathes, vertical milling machines, sawing machines, grinders etc. There are 3 axes to 5 axis CNC Machines. These are CNC controlled machines which are used with computer controlled numerical control machines. These machines are able to achieve finished and high tolerance parts. These machines have capabilities like

- Material of part

- Size of finished part

- Complexity of part

- Surface finish of part

The choice of machine is dependent on these parameters.

There are varieties of machines used for precision machining task as below:

- Milling Machines

The milling machine is used to removing material from workpiece by cutting operation with cutter tool which is rotating and removes material to shape the part to required size. These are used for cutting or machining of gears and complex parts, grinding and shaping of materials to accurate sizes. The lubrication is needed for these machining operations as there is heat generated in the parts to maintain accurate machining.

- Lathe or Turning Machines

The lathe machines are machines in which turning operations are done using the raw material which is rotated and use stationery cutting tools which will shape and change to part to required dimensions. There are capstone and turret lathe which are automatic and semi-automatic machine and CNC lathe machine.

- Boring Machines

The boring machines are the machines used for drilling highly precise holes using rotating cutter tools. These machines can drill holes of varying depth. The following machines fit into one of the above general categories of machine.

- Drilling machine

These are vertical drilling machine used drilling of holes with accuracy of center of hole and drilling of hole to a larger depth. The machine can drill hole of given diameter up to given has depth. The drilling machine are redial drilling machine which allows drilling of material for multiple holes.

- Lasar machines

These are machine which uses laser rays for machining operation for high precision required in the to produce the tiny parts or holes. They can produce the parts of size 0.75 inches in diameter with a tolerance of 0.0004 inches. They are tooled to high tolerances due to the lack of displacement and vibration.

- EDM machines

These are machine which uses the electric discharge for performing machining operation. The machines have electric discharge between two electrodes which performs machining operations. These machines are used for very high precision machining of holes and complicated parts.

3. Common Benefits

- The tolerances of parts are very close tolerances for manufacturing of parts

- It provides higher productivity due to low machining time

- It given higher surface finish due to low depth of cut

- The operations are similar so machining is accurate for each product

- It provides low rejection rate of products

- It has less removal of material

- It can allow design changes

- The complex parts can be machined very easily

How precision machining is beneficial for the manufacturing industry?

- The machining is done with high level of accuracy

- It will provide consistent quality of products manufactured

- It prevents less wastage of material due to low material removed from parts

- It provides better efficiency of production

- It provides part which is cost effective

- It provides safe operation during production

- The error and rejection are less

CNC Precision Machining

The tools used for precision CNC Machining are controlled by our skilled staff with the help of sophisticated digital systems. CNC, or Computer Numerical Control, allows for extremely particular control of positioning, velocity, coordination, feed rates, and other precision aspects of the manufacturing process for a particular part or object. The CAD drawing and drafting is done for given part and graphical simulation is performed for machining operation is done using the NC program. The CNC program contains the part programming code is created and part programming code is imported to Computer aided machine. Looking for top-notch CNC machining services? Explore comprehensive CNC machining service for rapid prototypes and production parts. Visit here CNC machining service. There are variety of machines which are used with CAD/CAM packages such as:

- CNC Lathes and Turning Machines

- CNC Milling Machines

- CNC Laser Machines

- CNC Electrical Discharge Machines (EDM)

- CNC Plasma Cutting Machines

Conclusion

In the above study, it is found that the precision manufacturing is necessary to obtain very close tolerances and better surface finish. The precision manufacturing improves productivity and lower rejection rates. The cost of product is reduced in mass manufacturing system due to higher productivity and rejection. The CAD/CAM system is most suitable system which can provide precision manufacturing. There are variety of operations done using CNC machine.