Reducing Costs and Waste: The Role of Big Data Analytics in Logistics Industry

Utilizing analytics is critical to guarantee the proper operation of supply chains and services in the globalized and interconnected society we live in today. The use of big data for logistics and supply chain management has become an important game changer in a sector that is becoming increasingly difficult to manage due to the growing complexity and volume of information generated by supply chains.

Without big data in logistics, the selection of materials, suppliers, stock places is completely manual. For example, the manager checks the database and makes a selection of carriers who regularly travel along this route or are ready to travel along it. Up to now managers needed to look for the optimal location, carrier and many other important points manually.

We see that businesses are in the process of creating a paradigm shift in how they do business today through the use of advanced technology and data analysis. In this article, we’ll look into the principal perks of big data analytics in logistics and transportation and how companies can benefit from the utilization of advanced technologies, newest trends, and tools.

Introduction to Big Data Logistics: Revolutionizing Cost Management and Waste Reduction

On average, it takes a specialist from 3 to 8 hours, just to form an offer and set a price to the client. And quite often, the work done is wasted because the terms of a deal are being updated quickly and often become outdated for parties to deal with. And until recently, there was no alternative to such a process. But now there is big data.

The logistician only needs to form a request to the system and enter key data. The specialist sets the date, direction, amount of material. Then the system already automatically makes a selection and forecasts a clear detailed plan of how it will be.

Correctly configured processing algorithms will show in a few seconds which transport of which carriers will be at the destination, let’s say, tomorrow. If this amount of vehicles on the route is enough, logisticians call specific contractors and after 10 minutes they can give the client an offer.

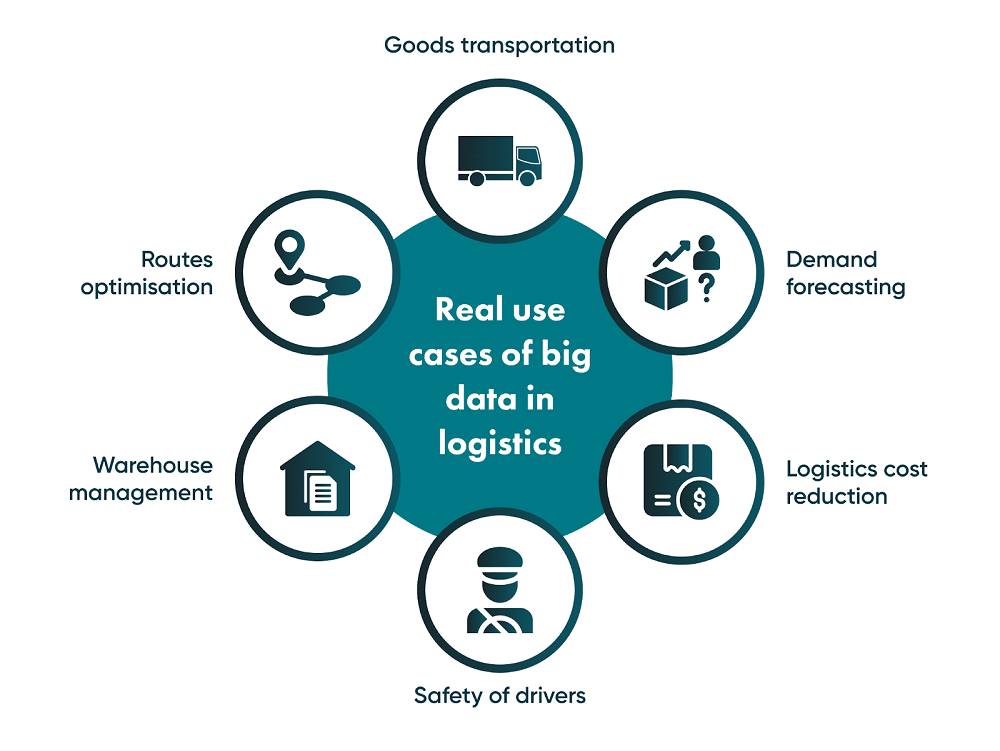

Big Data Analytics: Main Advantages

Logistical analysis is carried out on large and intricate data sets, commonly known as Big Data Analytics, to gather information about relationships, trends or other unknown aspects. In logistics, this calls for collecting and analyzing large amounts of data from various sources, e.g. sensors, GPS equipment, social networks sites such as Facebook or transaction logs. That information may be product availability, travel routes, weather patterns, behavior of customers and so on.

One of the main advantages of big data analysis in logistics and transportation is the improvement of cost management. Traditional methods of cost management are often based on historical data and general calculations, which do not fully reflect the dynamic nature of supply chains. This allows companies to see their operations in real-time and make data-driven decisions to optimize costs.

For example, by analyzing transportation data, companies can identify the most efficient routes, consolidate shipments, and minimize fuel consumption. Indeed, companies are able to find the best routes that allow them to aggregate transport and reduce fuel costs while achieving major cost savings through analysis of traffic data. Furthermore, large quantities of information may contribute to reducing the amount of waste in a logistics facility which can have an impact on both economy and environment because it is made up of surplus materials, unuseable material or inefficient processes.

Real-Time Analysis: Enhancing Cost Visibility and Waste Tracking

One of the major advantages of real-time analysis is the capacity to continuously control costs. Up until the point where it is no longer possible to detect cost overruns or inefficiencies, visibility of costs in the supply chain was only allowed for periodic accounts. Real-time analysis, however, enables businesses to keep track of costs throughout the entire period in question and quickly address any discrepancies or inconsistencies.

By analyzing data related to inventory levels, demand patterns, and production schedules, businesses can optimize inventory and reduce the risk of excess inventory. By tracking and analyzing equipment data such as fuel consumption and maintenance records, companies can identify and eliminate inefficiencies, extend asset life and reduce waste.

Many forms of running waste can arise in the supply chain, such as surplus stocks, inefficient movement, delays or lack of free resources. In order to improve operational efficiency, reduce costs and attain the sustainability targets, waste should be identified and eliminated.

For example, in 2018, DHL developed the Smart Truck solution to solve the problem of logistics costs. The company has equipped its trucks with IoT sensors that collect data on weather conditions, traffic jams, traffic accidents, etc. Through real-time big data analytics, the system optimizes routes, reducing transit time by up to 50% and providing over 95% online tracking reliability. Smart Truck reduced idle kilometers by 15%, saved millions of liters of fuel, reduced CO2 footprint.

Moreover, real-time analysis enables firms to respond quickly to market developments and customer needs. A company can respond to new trends, changes on the market or customer preferences through timely data. This knowledge will enable the logistics manager to optimize planning, anticipate needs and manage tasks more effectively.

Predictive Analytics in Logistics: Harnessing Big Data for Demand Forecasting and Resource Planning

Demand modeling is an important part of big data management. because it provides valuable information about people’s needs and requests. When using business analytics, accurate information can be produced by combining historical data with other important factors such as business growth, market conditions and price trends. This helps companies simplify the anticipation of data reduction needs for production and distribution.

Another crucial component of logistics management is resource planning. Businesses can utilize predictive analytics to improve the allocation of resources, such as personnel, transportation, or warehouse space, depending on their anticipated demand patterns. As we previously indicated, real-time insights enable organizations to make educated decisions, ensuring that resources are allocated effectively while eliminating wasteful expenses and extra time.

Naturally, big data and algorithms for their processing do not completely replace the logistician. In any case, the human factor remains, because at least you need to call the contractors and confirm the contracted volumes, and then discuss all the features of the task with the client and sign the necessary documents with him.

Along with the simplification of operational processes, logistics companies still have quite a lot of opportunities. Just one GPS sensor in the car allows market players to analyze the following parameters:

- Road congestion (analysis of traffic jams, causes and trends of congestion).

- Possible route difficulties for avoiding traffic jams in individual sectors of the city, identifying new emergency sections, poorly regulated intersections.

- Seasonality, the dependence of the volume of orders of the transport company on: productivity, good weather, and the quality of roads in certain settlements.

- Technical condition of units, consumable parts in vehicles.

Smart Routing and Optimization: Utilizing Big Data to Streamline Delivery and Reduce Costs

The ability to optimize and update routes in real-time is one of the main advantages of smart routing and optimization. Smart routing systems can foresee probable hiccups and proactively modify routing plans by assessing historical and actual data and incorporating external elements, such as weather forecasts and traffic data.

For instance, if a snowstorm is predicted along a certain route, the system can reroute vehicles to avoid the affected areas, thus ensuring timely delivery and preventing costly delays. These predictive capabilities empower logistics managers to operate with foresight, reducing the risks associated with unexpected events and improving resource usage.

Another interesting example. UPS has developed vehicle routing software to eliminate as many left turns as possible (in countries with right traffic). Indeed, the system develops routes in such a way that the number of left turns is no more than 10% of the total. According to the company’s managers, thanks to this, the company’s cars save 37,000 tons of fuel per year and emit 20,000 tons less carbon dioxide. The efficiency of route planning with navigation software helped the firm optimize the total number of trucks by 1,100 and reduce the total length of routes by 45.8 million kilometers per year.

If a certain truck is consistently running below capacity on a particular route, the system can identify opportunities to consolidate shipments or adjust routing to ensure full load utilization. This not only reduces costs associated with excess capacity but also decreases the number of vehicles on the road, leading to lower carbon emissions and a more sustainable logistics operation.

Automation and AI in Modern Logistics Practices: Leveraging Power of Smart Technologies to Boost the Performance

Automating logistics is the use of smart systems, robots and other sophisticated technologies to carry out tasks which have traditionally been performed by humans. With unprecedented speed and accuracy, automated systems are capable of dealing with complex tasks like order processing, inventory management or transportation optimization. The result is fewer human errors, better productivity and faster processing time.

One example of automation is the deployment of autonomous vehicles. Self-driving trucks and drones are increasingly being used for transportation, facilitating faster and more precise deliveries while eliminating the risk of human error. Automated warehouses, equipped with robotic systems, can efficiently pick, pack, and sort products, reducing manual labor and optimizing inventory management.

By facilitating data-driven decision-making, artificial intelligence is a key component of contemporary practices. Huge amounts of data can be analyzed by AI algorithms, which can then be used to predict trends and gain insightful knowledge.

Chatbots and virtual assistants powered by AI improve customer service by delivering real-time information and responding to inquiries more quickly. Additionally, by taking into account elements like traffic congestion, customer demand patterns, and weather conditions, AI algorithms can optimize supply chains.

The following are just a few advantages that result from the use of automation and AI in modern logistics practices.

1. Enhanced efficiency: The elimination of labor-intensive manual processes by automation and AI technologies results in an improvement in efficiency throughout the supply chain. Faster order processing, shorter lead times, and greater customer satisfaction are made possible as a result.

2. Increased accuracy: Smart technologies reduce human error, ensuring accurate inventory management, order fulfillment, and transportation planning.

By doing this, the likelihood of expensive errors or operational delays is greatly reduced.

3. Savings: Automation and AI enable operational cost optimization by removing pointless labor, cutting fuel consumption through effective route planning, and lowering stock holding costs through improved inventory management.

4. Scalability: AI algorithms and automated systems can modify their operations to accommodate changes in demand patterns. Due to their ability to adapt, businesses are able to support growth without sacrificing efficiency.

Conclusion

Companies will be able to gain instant visibility into their business operations, optimize costs, reduce waste through the power of modern technology and data analytics. In this way, it helps to increase productivity, improve customer satisfaction and enhance environmental sustainability. The potential for huge amounts of data in logistics will only grow as technology evolves, thereby providing companies with an important tool when they are trying to stay competitive in the digital age.

However, we advise not to forget about consulting and using the help of trusted vendors who can provide your company with high quality custom logistics software development services. Big data and logistics are growing exponentially at the moment, therefore, seasoned IT experts with the experience in the industry would definitely be a hard but precious find for businesses who want to boost their workflow fast and efficiently.